Omni-Threat Structures’ has secured its entire supply change with multiple quality chests along the process. Custom aggregate selection for chemical properties, custom crushing for aggregate size control, and custom blending and sacking done with a computer controlled apportioning system at our facility in Milan TN. The blending facility is housed in an 80,000 SF building for ample space of finished product storage, including 40,000 SF for stockpile with weather shelter.

Mining

Services

Crushing

Washing

Stemming

Dry Cobbing

Material Transfer

Material Recovery

Railcar Loading

Railcar Cleaning

Road Maintenance

Road Construction

Mine Stripping

Mine Reclamation

Utility Installation

Utility Repair

Snow Removal

Ground Thaw

Frost Protection

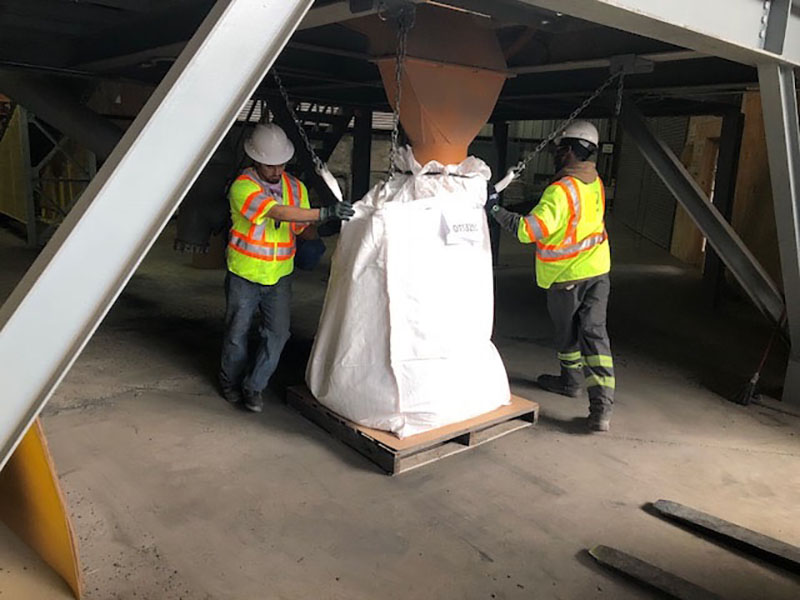

Mix Design Aggregate Processing, Blending & Sacking

Omni-Threat Structures aggregate processing, blending and sacking is done at a facility housed in an 80,000 SF building for ample space of finished product storage including 40,000 SF for stockpile weather shelter. It has a state-of-the-art computer controlled mixing plant capable of blending up to 8 different components for high production finished products in bags or supersacks.

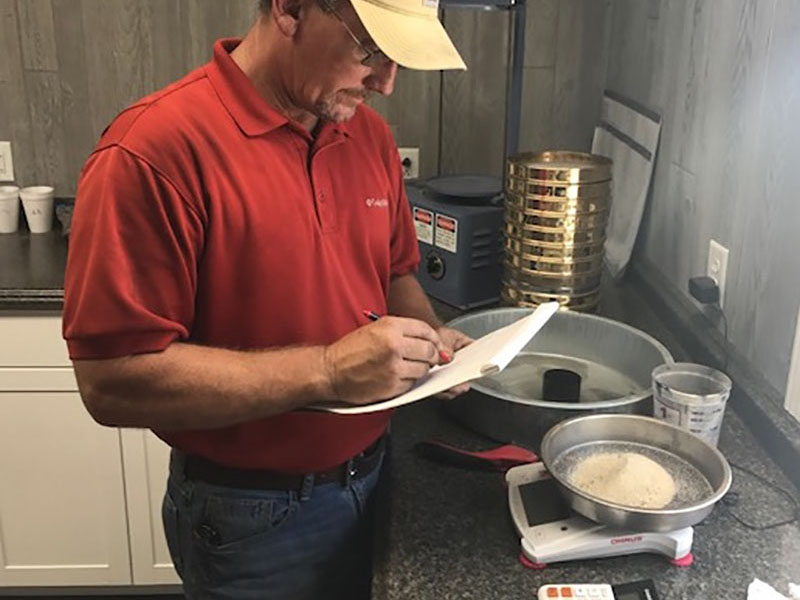

With an onsite laboratory for superior quality control, raw materials can be tested as they come in. The facility has a rail car unloader installed, which is located within 200 feet of the plant. With the existing capacity of the rail system within the Army base, it is a perfect installation for processing a high volume of raw material delivery. Further, the facility uses an onsite drying system for processing several types of aggregates, making it a very versatile aggregate processing plant for blending and bagging of nearly any type of mixtures.

Faster build time

Multiple threat capability

Cheaper combined structure & shielding system

Significantly increased longevity & decreased maintenance

Increased fault tolerance

Ease of interior installation