IBC-compliant Concrete Practice Reaches Electromagnetic Pulse Shielding

Concrete Products Magazine / December 19, 2018

Miami-based American Business Continuity Group reports breakthrough construction methodologies and proprietary conductive shotcrete shielding to protect buildings from High Altitude Electromagnetic Pulse, Intentional Electromagnetic Interference, Emanations Eavesdropping, natural disasters, and ballistic or blast loads.

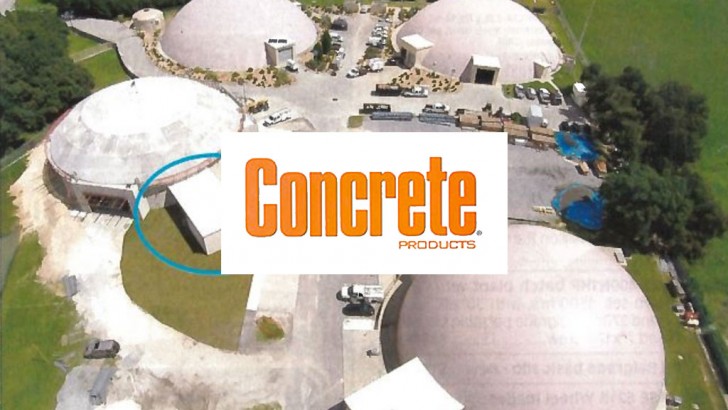

The contractor announced in December 2016 completion of an EMP (electromagnet ic pulse) shielding compliant prototype at a Lakeland, Fla., group of specialty structures dubbed the Disaster Recovery Complex. The structure stems from joint research with the University of Nebraska-Lincoln (UNL); technology developed during the three-year pro gram has been exclusively licensed by ABC Group from NUtech Ventures, the school's commercialization affiliate.

Decades of research in conductive concrete and EMP shielding under UNL Professor of Civil Engineering Christoper Tuan and Professor of Electrical and Computer Engineering Lim Nguyen preceded the commercial pur suits of ABC Group, whose proprietary construction methods utilize patent-protected EMSS-Electromagnetic Shielding Shotcrete. The methods yield high strength, rigorous ly tested structures that exceed the electro magnetic shielding requirements of Mil-Std 188-125 as well as the higher frequencies of Intentional Electromagnetic Interference weapons and Tempest.

"EMP is very lethal to electronic equipment," says Professor Tuan. "We found a key ingredient that dissipates wave energy. This technology offers a lot of advantages to the construction industry is very interested."

"The concrete can provide what we call a multi-threat structure ... able to withstand an explosive. electromagnetic attack or other schemes" adds Professor Nguyen.

ABC Group's Omni-Threat Structures include scalable, cost-effective hardened buildings configurable to customer-defined levels of protection for critical infrastructure, power generation, and distribution facilities, and military or financial institutions. Com pared to traditional methods requiring a separate metal shell within a building, ABC Group constructs a single structure combin ing the physical security of concrete with electromagnetic shielding. The method results in what engineers note are a short er, more economical construction cycle and lower building life-cycle costs. Elimination of the building within the building, moreover, negates the need for separate architecture, engineering, and specialized construction.

Specific to the power grid, ABC Group buildings offer secure storage of replacement electronic devices including test equipment and diagnostic sensors. Particularly vulner able applications include regional command centers, substations, disaster recovery facili ties, operations control buildings and Supervisory Control and Data Acquisition rooms.

The firm has logged three decades as an industrial general contractor, plus a decade in specialized design-build services delivering power industry customers hardened, Nuclear Regulatory Commission-grade structures.